Particle Impact Noise Detection

PIND BW-LPD-DAQ4000

- Computer based controller with predefined MIL-STD test sequences stored (New)

- Create unlimited custom tests with multiple vibration frequencies and acceleration and other parameters to meet unique requirements (New)

- Easily store and recall custom test (New)

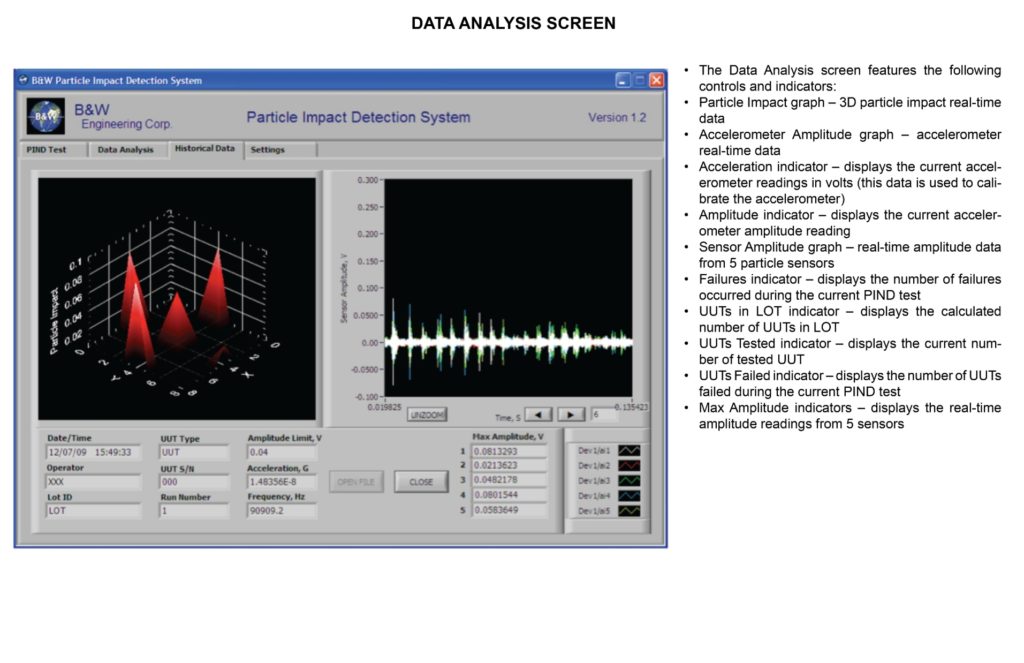

- Continuous on screen display of test frequency, vibration level, etc.

- A custom shaker capable of testing packages up to 5kg/10lbs at 20gs (See BW-LPD-DAQ-4000HD pages)

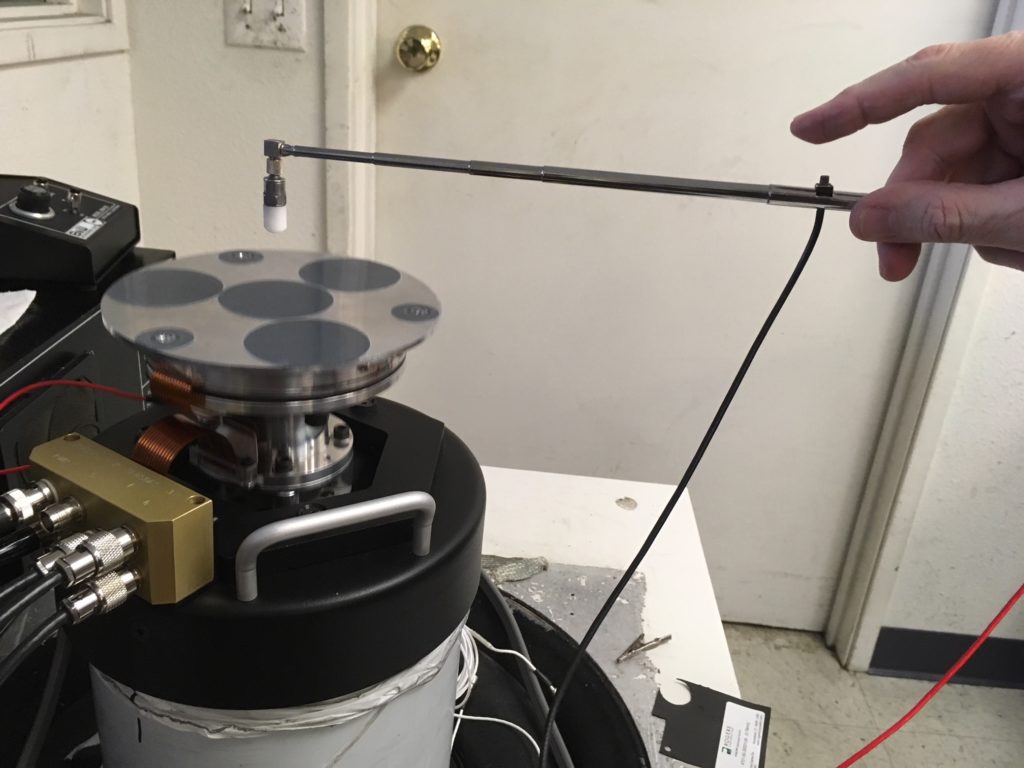

- A custom test platen with up to 5 particle detection sensors (New)

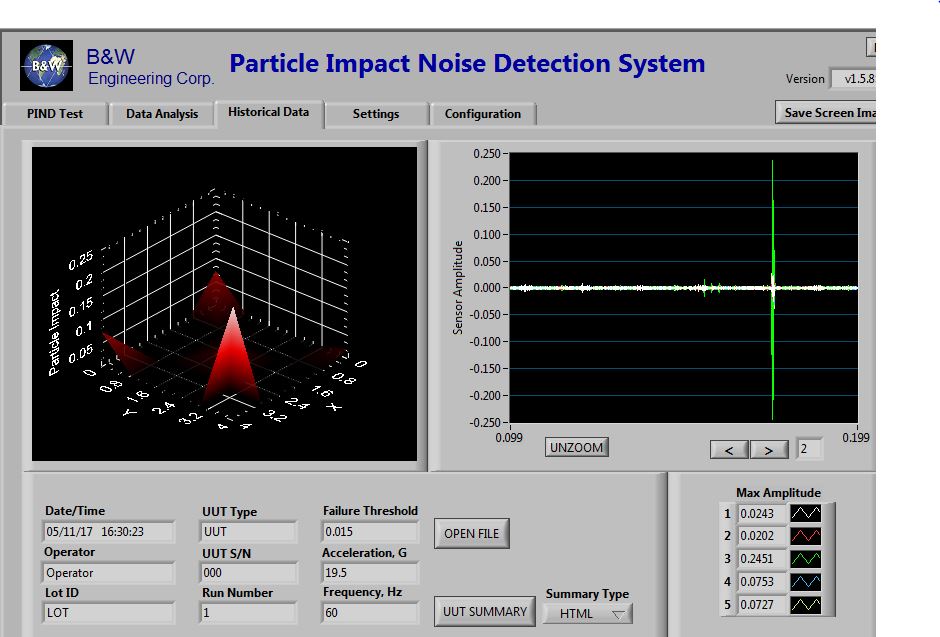

- On screen monitoring of signals created by loose particles

- On screen indicator signals particle detections

- Audio monitoring of signals created by loose particles

- Stops the test when particle noise threshold is exceeded (user selectable)

- Easily store and recall test results (New)

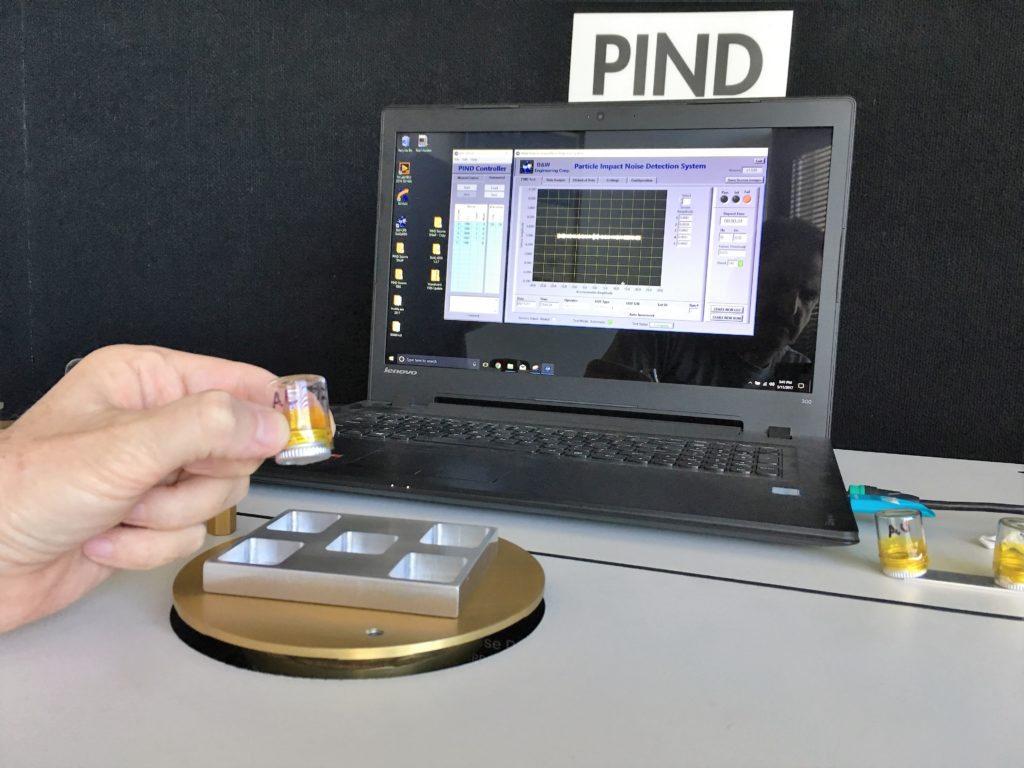

- Supports both fully automatic and manual operation modes

- Sensitivity Test Unit (STU) provided to verify MIL-STD compliance

PIND CONTROLLER

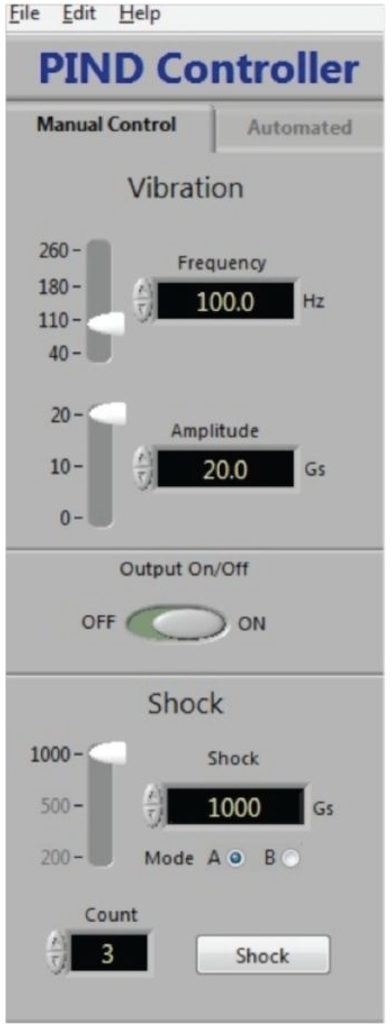

MANUAL MODE

The versatile Manual Mode is useful for experiments and can apply a vibration frequency sweep (to find resonances that make particle type noise) and apply shocks simultaneous with or without vibration. The shock level, count and application can be chosen. In Manual Mode the user has complete control over Vibration frequency and acceleration level and the shock.

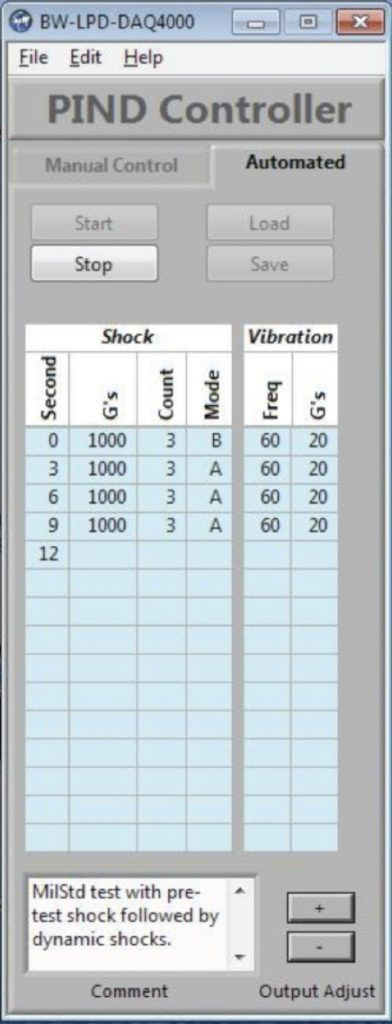

AUTOMATED MODE

The unique Automated feature allows users to easily create PIND Test Profiles with unlimited Frequency and Acceleration choices that can be saved and recalled for future use. In Automated Mode detections are automatically saved for future analysis and logged for Test Report with percent defective calculation.

Download: BW-LPD-DAQ4000 Brochure

Download PDF: BW-LPD-DAQ4000 User Manual

Download: Install BW-LPD-DAQ4000 Demo Zip File

Download PDF: Upgrade Flyer BW-LPD-D4000 to a New BW-LPD-DAQ4000

Download PDF: Upgrade Flyer – BW-LPD-B2000 to BW-LPD-DAQ4000

Download PDF: Instructions For Returning BW-LPD-DAQ4000 For Calibration Service

Download PDF: Instructions For Returning BW-LPD-D4000 For Calibration Service

Download PDF: Instructions For Returning BW-LPD-B2000 For Calibration Service

The BW-LPD-DAQ4000 is designed to detect loose particles in all kinds of products from your smallest integrated and discrete components, to your largest hybrids and subassembly packages. With speed and accuracy critical to your bottom line, the BW-LPD-DAQ4000 allows you to quickly select your test of choice and begin automatically testing without fiddling with knobs or entering complicated programming steps.

The BW-LPD-DAQ4000 comes preprogrammed to meet or exceed MIL-STD-883 Method 2020 for hybrids and MIL-STD 750 Method 2052 for discrete devices and MIL-STD-202 for relays and switches and stores the results of each test run.

B&W Engineering Corp., the originators of the first fully MIL-STD compliant PIND system, is pleased to introduce the next generation in PIND systems. We are raising the bar, combining the quality and accuracy you expect from B&W Engineering with the ease and flexibility of automated programming never before found in any PIND system.

But we didn’t stop there, we’ve incorporated the largest shaker ever available and a multi-sensor test head to give you the most versatile PIND system ever produced.

See the BW-LPD-DAQ4000HD for up to 10 Lb. payload

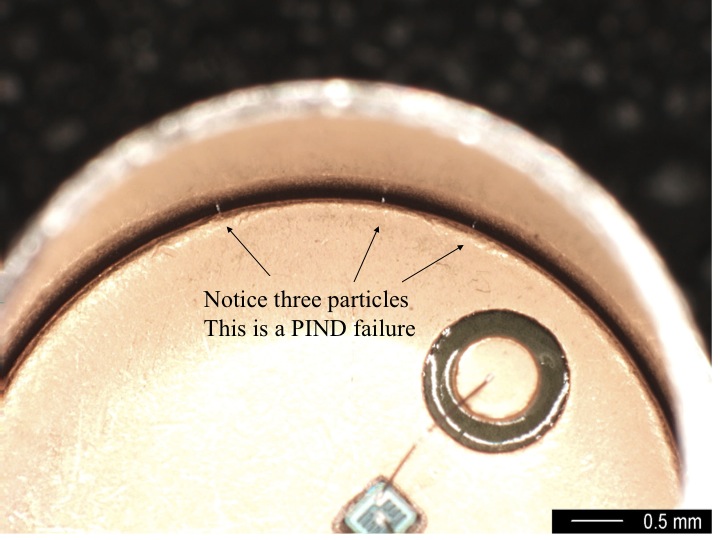

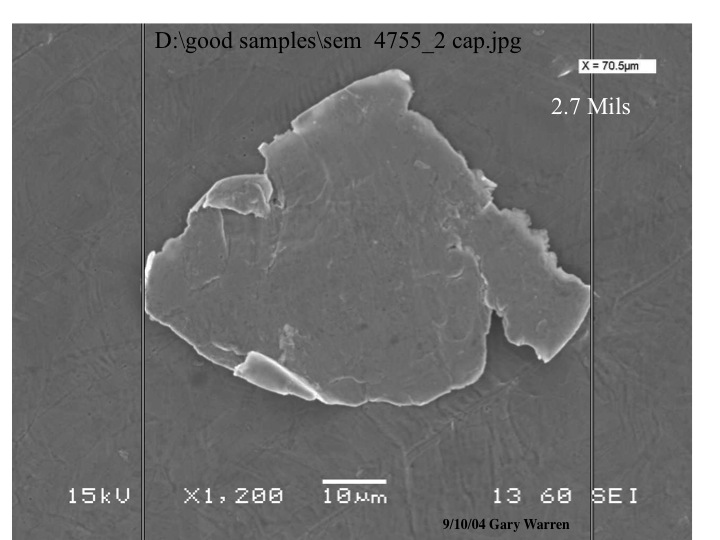

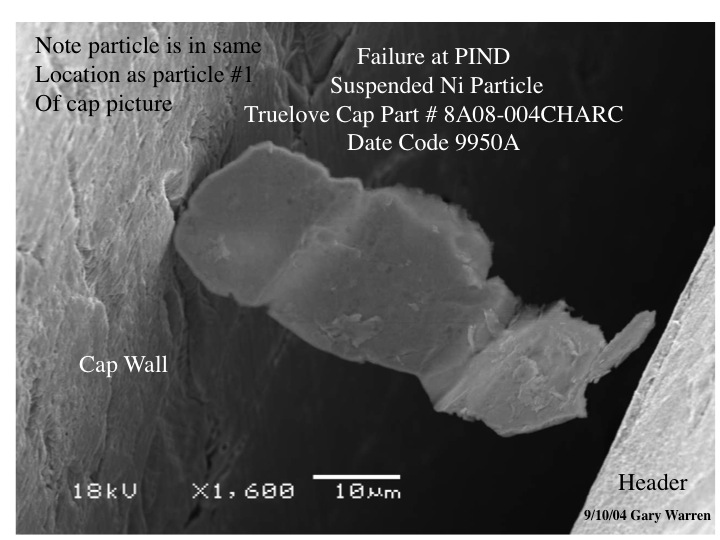

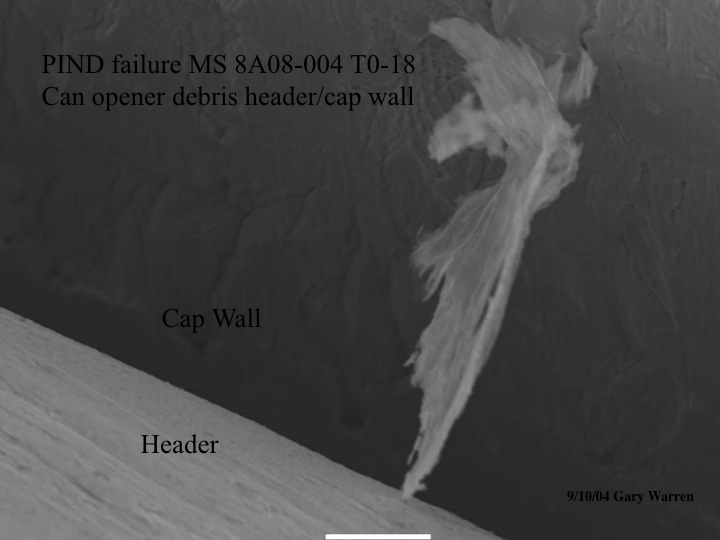

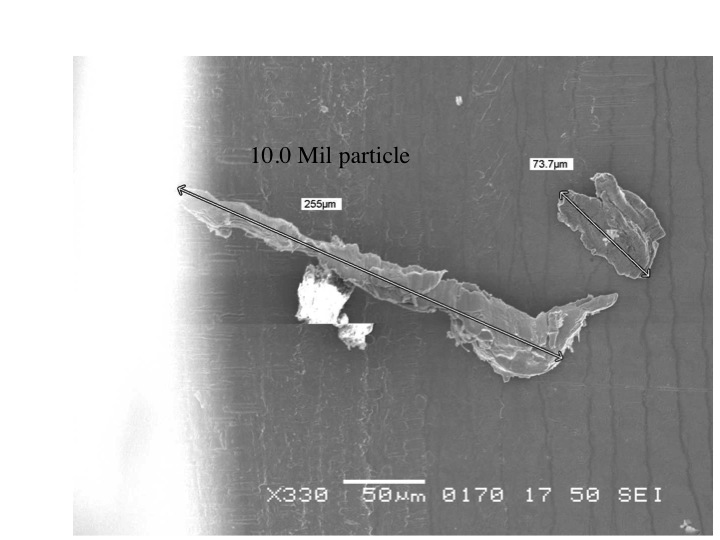

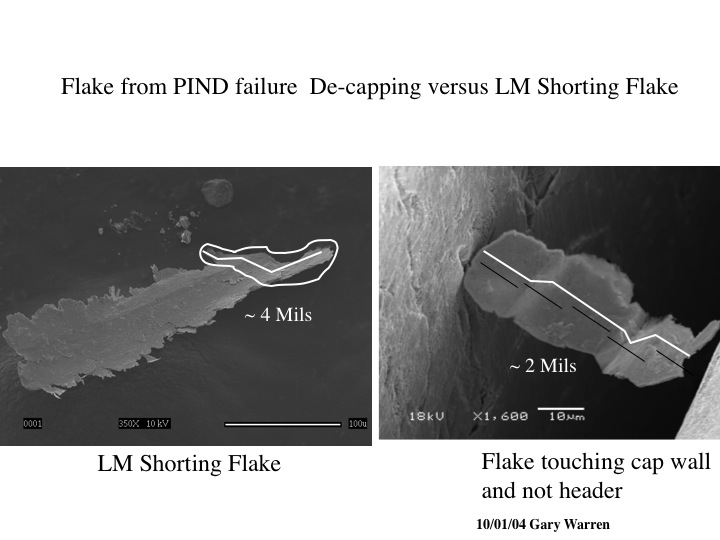

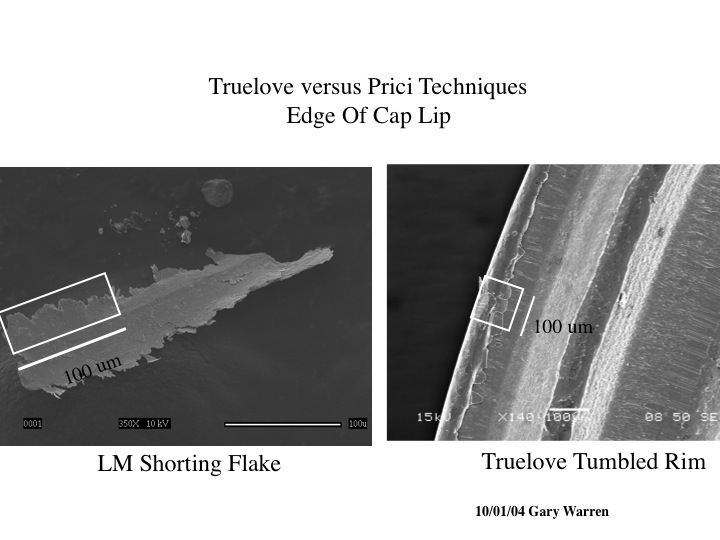

Gallery of Particles (Click image to enlarge)

Features

Designed for flexibility and to handle your toughest testing needs, large and small.

- Programmable – Create, save, and recall test configurations to meet your changing needs

- Large multi-sensor test head (up to 5)

- Record, save, and view real-time test data for failure analysis

- Large shaker capable of handling very large test subjects

Videos

DAQ4000 Test Report

BW-LPD-DAQ4000

Unfortunately the MIL-STDs were changed to allow the inferior shock technique of a non-simultaneous shock (“perturbed”), allowing the shaker to stop, shock itself into its stops with a thud and resume vibration. Even the shock duration was changed to a non-standard reference to 50% of amplitude instead of 10% as with all other shock duration measurements. This technique allows smaller particles to re-adhere before the vibration resumes, is more destructive to the device under test by over-stressing it causing micro-cracks, compromising wire bonds and other latent mechanical defects, and ultimately breaks the shaker with costly repairs and downtime.

The shock is the single most important part of the PIND test to detect the smallest particles. Small particles have a very high resonance frequency, so a high frequency shock is the most effective at knocking them loose while stressing the device under test the least. One PIND manufacturer has made the claim that an isolated test at lower frequency, higher amplitude shock at 40% of device maximum was more effective (if you cannot shock simultaneously). This claim does not agree with facts or physics.

The highest frequency mechanical shock is generated by impacting harder materials at higher velocities. For the purposes of PIND testing the minimum shock pulse duration possible is about 50 microseconds. The MIL-STD used the < less than requirement intending to minimize the shock duration, there is no such thing as a Zero Time shock except in theory and it would have infinite Amplitude. This duration will extend naturally as mass is added, so the larger package’s response to an identical shock to a smaller mass will be longer commensurate with the mass, material and geometries, creating what is referred to as the Transfer Function.